PepsiCo, the world-renowned food and beverage giant, has taken a substantial step towards a more digitalised future. In partnership with Dematic, they have incorporated automation as a key function within their developed production and logistics facility in Rojana, Thailand. This facility is a considerable regional hub, involved in the production of various goods. The enhanced capacity is in response to escalating demand for PepsiCo products within Thailand.

Colin Matthews, Supply Chain Senior Director – IndoChina Foods, PepsiCo, stated, “Rojana is one of our biggest plants, and it also has several different product platforms. We have potato chips, we have Stax-brand chips, and we have Fry Pack in extruded products as well...Those products are made at Rojana and are not only distributed nationally across Thailand, but also internationally to Vietnam and other neighbouring countries.”

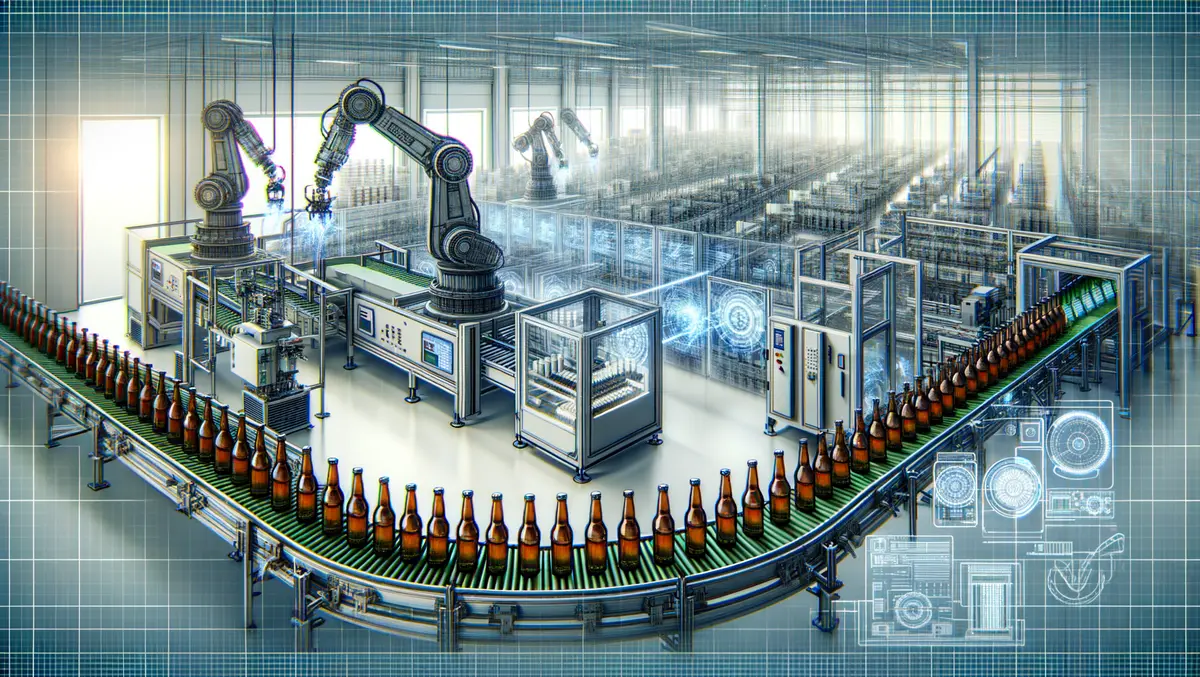

Dematic and PepsiCo collaborated to develop an automation solution to overcome storage, throughput capacity, and productivity obstacles within their logistical operations. The resulting infrastructure revolves around an Automated Storage and Retrieval System (AS/RS), with a direct interface to both the order fulfilment and production areas.

Charan Techapattaraporn, Logistics Manager at PepsiCo, explained the rationale behind the move, “We foresee a manpower shortage being a major challenge for our local operations in Thailand...Automation, therefore, is the perfect solution to take on this challenge, whilst also improving our facility operations across the board.”

The advanced AS/RS is projected to be crucial within PepsiCo's strategy to augment its logistics effectiveness and productivity levels in the Rojana facility. With it, corporations can manufacture and store products efficiently and sustainably until they are required for assembly and shipment to customers.

Echoing this sentiment, Phamondate Rukdee, Sales Manager at Dematic Thailand, stated, “The AS/RS is at the heart of PepsiCo's strategy to enhance its production and logistics efficiency at the Rojana facility...It provides an extremely space efficient way to store products between when they are manufactured and when they need to be assembled and despatched for delivery to customers.”

Moving beyond the benefits highlighted, the Dematic AS/RS solution also enhances warehouse operator safety by significantly reducing the quantity of forklift trucks and other materials handling equipment. This in turn, minimises potential for accidents, injuries, and damage to both individuals and equipment. Furthermore, the Dematic solution has been designed with the future in mind, enabling the facility to expand in accordance with additional growth and adapt to shifting business needs and requirements.

“The partnership between PepsiCo and Dematic exemplifies the potential of automation to enhance operational efficiency and safety while also laying a solid foundation for sustained growth...Together, we have achieved great results and positioned PepsiCo for an even stronger future,” concludes Rukdee.

.webp)